by Kerry Lutz

Financial Survival Network

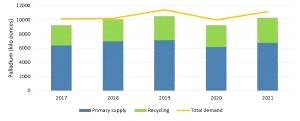

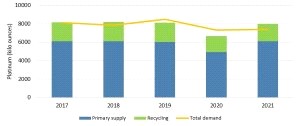

Regenx Tech’s (TSX-V: RGX- OTCQB: RGXTF) CEO Greg Pendura has spent years developing its proprietary precious metals recovery process that reclaims 90+% of palladium and platinum found in diesel catalytic converters. The majority are now relegated to the nation’s landfills. 85% of the world’s supply of palladium (Pd) is used in catalytic converters. 2,110,000 oz of palladium was used in the production of catalytic converters in North America in 2021 or nearly USD 4 billion at current metals prices. The economics of the global platinum market are similar; diesel converter recycling would help meet current and future demand.

The majority of the global platinum/palladium market is provided by South Africa and Russia. Supply disruptions have taken place in both countries for different reasons. Economic and political challenges have hampered South Africa’s production. The Ukraine War has undermined trade in Russian sourced platinum and palladium. Efficient clean recovery of PGM’s would help solve these supply issues.

Every year over 24 million diesel catalytic converters are retired. While a large percentage of gasoline converters are recycled, only 30% of diesel catalytic converters are reprocessed. The remainder are relegated to landfills since smelters are hesitant to accept diesel converters, due to environmental hazards, processing inefficiencies and limited capacity. This represents an environmental hazard. Yet the global catalytic converter market continues to grow and is forecast to reach USD 73.1 billion by 2025. Electric vehicles will not replace non-road heavy equipment and yellow Iron in the foreseeable future, so the numbers will keep growing.

Global demand and supply of palladium

Global demand and supply of platinum

Pendura long ago recognized this opportunity and set out to develop technologies and systems that could recover these metals at a 90% or greater rate. Recent technical developments indicate that rhodium, a metal also present in many converters, can also be extracted using the Regenx process, thus upping the recovery ante.

Once its US pilot plant came on stream, Regenx then financed its commercial plant construction via an oversubscribed rights offering. Construction in Johnson City Tennessee is nearing completion. Major investor and partner Davis Recycling (the leading US catalytic converter recycling company) provides Regenx with a virtually inexhaustible supply of retired diesel catalytic converters. When needed, Davis can easily expand this supply chain to cover most of North America, as Regenx starts expanding its footprint.

Regenx’s unseen domination of the supply chain will make it extremely difficult for new entrants to capture market share. While it may be possible to clone the technology, it is virtually impossible to duplicate the complex supply chain that brings the diesel catalytic converters to Regenx’s doorstep. The auto scrap business is extremely fragmented, with thousands of recovery companies funneling their materials into the distribution process. It has taken Davis Recoveries decades to build a reliable supply chain that gets the materials to the right place at the right time. CEO Ben Davis proclaims that he’s an urban miner and his operation’s profitability may be the envy of more traditional miners.

A 90+% palladium and platinum recovery rate mean that Regenx will be approaching production of 3000 grams per ton. Pendura is confident that one full scale four module plant can produce over $100 million in revenue per year. Margins are extremely rich and this will make Regenx one of the world’s most profitable mining entities.

The technology is extremely scalable and Pendura looks forward to the day when there will be multiple recovery plants annually extracting millions of ounces of Platinum and Palladium around the globe. It has been a hard-fought battle to develop and perfect the technology. For now, the company is in its implementation phase and the opportunities are tremendous.

Plant construction is slated for completion in Q! of ’23, with production beginning in Q2 ’23. Regenx USA division president Rick Purdy, has moved with his family from Vancouver to Tennessee (over 2000 miles) to take advantage of what he calls “the opportunity of a lifetime.” He is that convinced that the company will use its technology to dominate the precious metals recovery space and provide great opportunities to investors and employees alike.

Regenx is an example of clean Greentech that has achieved profitability without the benefits of government subsidies. However, the company is exploring the availability of carbon tax credits as this will further enhance and improve the returns to shareholders.

With the imminent opening of the Tennessee facility, Pendura is ready to take the company to the next level. If things go the way he expects, cash flow will rapidly accelerate. This will enable him to plan future plants around the country and then across the globe.

Regards,

Kerry Lutz

The IP infringement lawsuit is an overhang on this stock.

https://www.bccourts.ca/jdb-txt/sc/22/01/2022BCSC0180.htm